Plastic from renewable resources is already commonly available on the market, but terms such as ‘bioplastic’, ‘biodegradable’ or ‘compostable’ can be confusing for consumers. These terms are often used to create a positive impression about the material and to suggest to consumers that they are using an eco-friendly product. Where this may be true in a lot of cases, it is not always the case and there is a lot of confusion around what can be branded under the umbrella of ‘eco-friendly’. In this article, we try to explain the main differences between different types of bioplastics and the misconceptions around them.

Bio-based v. Biodegradable v. Compostable

All compostable items are biodegradable but not all biodegradable items are compostable. Compostable usually refers to something that is bio-based, that is an item that is wholly or partially derived from renewable resources.[1] This is not necessarily the case for biodegradable products. Biodegradable means that an item or product will biodegrade at some point in time[2]. This could take 5,000 years; there is no limit to the time that an item takes to fully biodegrade. Thus, even a rock could be classified as biodegradable. However, all three are considered bioplastics.

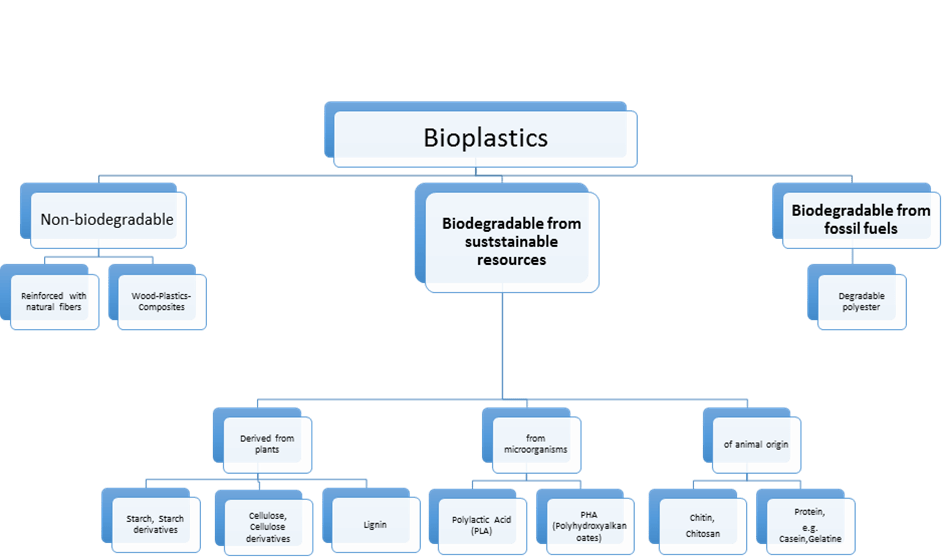

Plastics from renewable resources are referred to as bioplastics or biopolymers, though these terms are not clearly defined. To date, the prefix ‘bio’ has been used to convey two different properties, namely if a product is bio-based or biodegradable [3]. Bio-based products can be both organically derived and biodegradable.

EU standard DIN EN 13432 regulates which materials can be classified as compostable (fully disintegrates within 12 weeks) and biodegradable (within 6 months). If certain conditions are met regarding the time, temperature, humidity, oxygen levels and presence of microorganisms or fungi, the material will degrade by up to 90 percent or more back to water, carbon dioxide and compost (biomass).

All compostable items are biodegradable, but not all biodegradable items are compostable. Nevertheless, both are bioplastics.

It is also worth mentioning that it is not just plastics from renewable resources that are biodegradable. Some plastics from fossil fuels are also capable of biodegrading under certain conditions [4]. For a detailed overview of the different sorts of bioplastics and how they are categorised, see Figure 1 below.

In the following sections, we will discuss two types of plastic and explain the complexity of the material and how that affects our ability to recycle it.

PLA (polylactic acid)

PLA is a synthetic polymer related to polyester that is derived from fermenting starchy plants such as corn. PLA is often blended with other plastics. PLA is usually compostable in commercial composting facilities but might lose that property once blended to achieve certain characteristics. If compostable plastic ends up anywhere other than an industrial composting facility, the outcome is the same as for any other plastic material.

Currently, PLA is mostly used in single-use packaging for cold drinks, fruits, vegetables or meat. To achieve longer durability, PLA can be reinforced with natural fibres for higher levels of strength and durability. Bamboo cups are one example. PLA blended with natural fibres is starting to be used in the automotive industry to replace conventional fossil fuel-based plastics. It has also been used in the medical field for years due to its property to be naturally degraded within the human body and is a very popular filament among the 3D printing community. Most of us encounter PLA almost every day.

WPC (Wood-Plastics-Composites)

WPCs are thermoplastic composites that are commonly found in the construction and furniture industry. They are made from polyethylene or polypropylene combined with up to 80 percent wood flour and other additives such as bonding agents, UV protection agents and pigments[5]. Together with PLA resin, these composites offer mechanical and physical properties that make them suitable for a wide range of applications while being both biodegradable and compostable (Natural Fibre Bio)[6].

Composting v. Combusting v. Recycling

In 2014, 39.5 percent of Europe’s plastic waste was processed via energy recovery processes[7]. Another 31 percent still ended up at landfill sites, where it was set aside as an unused (valuable) resource with the potential to pollute the environment if committed to landfill. From all angles, landfill is the least favourable option for waste management[8]. Toxic substances can drain into the groundwater over time creating a huge environmental hazard[9].

A growing, but still insufficient proportion was recycled. Recycling of PLA is carried out in the same way as with fossil fuel-based plastics. Because of the similar chemical properties, plant-based plastics can under some conditions be mixed with fossil fuel-based plastics during the recycling process. However, mixing recycled plastic with PLA is usually avoided.

Even though PLA has many benefits, as mentioned above, there are also some downsides to its current use. There is a danger of soil acidification when agriculture tends to monoculture to grow sufficient feedstock for PLA production (e.g. corn and other starchy plants), especially if genetically modified plants are used. The German Federal Environment Agency (Deutsches Umweltbundesamt) estimates that the majority of feedstock grown for the production of PLA comes from GMOs (genetically modified organisms)[10]. This concern has to be well addressed as demand for compostable plastics is only expected to grow. The benefits or concerns surrounding GMO crops are not discussed in this whitepaper.

One major issue remaining is consumer confusion about compostable plastics. Products that are labelled with the seedling logo (Figure 2) are officially suitable for composting. However, these products do not degrade fast enough or add sufficient nutritional value for commercial composting facilities to regard them as valuable. In most cases, they have come to be considered as more of a nuisance than a benefit. Non-biodegradable plastics may also accidentally be mixed with the supply of organic waste and have to be sorted, which often needs to be done manually at the composting facilities – a timely and labour-intensive task. PLA products can be identified using near-infrared scanners, but the equipment is expensive and the return is too small to make them commercially viable at this point. Nevertheless, to suggest that fossil fuel-based plastics would be environmentally advantageous due to these problems is plain negligent considering the damage oil exploration has done to our environment to date.

Bio-Labels

There is another factor causing confusion around bioplastics, namely labelling regimes. With a multitude of bio-labels on the market, it is easy for consumers to get lost or be misled. For example, the number of eco-labels (including bio-labels) worldwide is currently tracked at 456 labels in 199 countries and across 25 different sectors[11]. Therefore, there is justifiable concern about the potential for the mishandling of bioplastics[12]. Critics are concerned about the potential for increased littering because of contradictory messages from different industries about the environmental friendliness of different forms of bioplastic[13][14].

456 ecolabels in 199 countries 25 different sectors

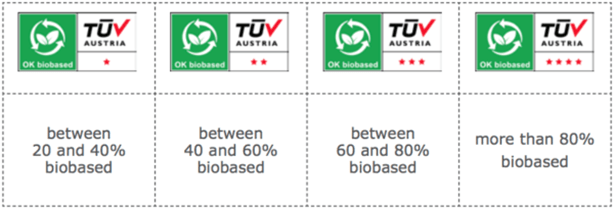

Below is the most common labelling format used within the EU to identify bio-based products. Note that the only difference between the various labels is the number of stars in the bottom right corner. These labels are also used without any explanatory text, leaving consumers to make an educated guess when buying these products what the number of stars means about the percentage of bio-based material the product contains. The remainder may be made up of fossil fuel-based plastic.

Credits European Bioplastic

The use of the word “bio-based” tells us nothing about the potential of the product to be composted. It is no surprise that there are different labels for that. Compostable plastics sound like every plastic manufacturer’s dream: comparable properties to traditional plastics, but without the ecological footprint. However, this is a major misconception about compostable plastics. If they are not collected separately, they are handled in the same way as traditional plastics that are incinerated, sent to landfills or similar. Many might believe that compostable plastics are the solution to the single-use plastic problem, but the truth is, that they are still undesirable single-use items. Additionally, they could even stimulate the wrong usage of plastics given all the reasons mentioned above.

The two main flaws of the bioplastic industry are:

- The lack of collection schemes for the different kinds of plastic.

- The multitude of labelling schemes results in a high probability of consumer confusion.

These flaws create an environment that hardly produces a dent in the plastic pollution problem. Ultimately, the responsibility to do something about these problems rests with big manufacturers and ecolabelling organisations. Corporate Social Responsibility might work in the minds of consumers, but Mother Nature will not be tricked so easily.

Author

Philip Ehrhorn

Philip is the co-founder and CTO of The Great Bubble Barrier with a background as a Naval Architect and Ocean Engineer with additional education in Aquatic Ecosystem Analysis. He has a strong focus on plastic materials, and recycling methods and knows how to debunk the many plastic myths.

References

1. EUBP (2016). “What are bioplastics?.” European Bioplastics , Fact Sheet.

2.UBA (2009). “Bilologisch Abbaubare Kunststoffe.” Umweltbundesamt.

3. Ibid.

4. Ibid.

5. UBA (2009). “Bilologisch Abbaubare Kunststoffe.” Umweltbundesamt.

6. Petinakis, E., Yu, L., Simon, G., Dean, K. (2013). “Fiber Reinforced Polymers – The Technology Applied for Concrete Repair.”, Chapter 2: Natural Fibre Bio-Composites Incorporating Poly(Lactic Acid), 41-54

7. EUBP (2016). “Bioplastics – furthering efficient waste management.” European Bioplastics , Fact Sheet.

8. EUBP (2016). “Bioplastics – furthering efficient waste management.” European Bioplastics , Fact Sheet.

9. Vaverkove, M.D. (2019). Landfill Impacts on the Environment. Geosciences, 9(10), 431

10. Detzel, A., Krüger, M. (2006). “Life Cycle Assessment of PLA – A comparison of food packaging made from NatureWorks® PLA and alternative materials.”, IFEU GmbH Heidelberg. Final Report.

11. Ibid.

12. European Parliament. (2018a). Amendments 223 – 526. Retrieved from

13. Napper, I. E., & Thompson, R. C. (2019). Environmental Deterioration of Biodegradable, Oxo-biodegradable, Compostable, and Conventional Plastic Carrier Bags in the Sea, Soil, and Open-Air over a 3-Year Period [Research-article]. Environmental Science and Technology, 53(9), 4775–4783.

14. Nazareth, M., Marques, M. R. C., Leite, M. C. A., & Castro, Í. B. (2019). Commercial Plastics Claiming Biodegradable Status: Is This Also Accurate for Marine Environments? Journal of Hazardous Materials, 366, 714–722.