Plastic is a popular product which is widely used, with an increase in global annual production from 2 million tonnes in 1950 to over 400 million tonnes today [1]. A major reason for the success of plastics is their material properties: lightweight, durable and cheap. However, these properties are also the reason why plastic pollution in our environment has such a devastating effect. While plastic is often praised for its recyclability, unlike glass or aluminium, plastic is much more difficult to recycle. Here, we aim to answer some of the most common questions and misconceptions about plastic recycling.

Types of Plastics

To understand the challenges involved in recycling plastic, it is important to understand the chemical properties of different types of plastics. There are thousands of types ranging from soft films used for food wrapping to rigid sturdy plastics for industrial purposes. Some types of plastics have quite a similar chemical structure, others are quite different in form and composition. Most virgin plastics are made from fossil fuels, but plastics made from renewable sources such as cornstarch are on the rise. You can find more information on bioplastics in our whitepaper.

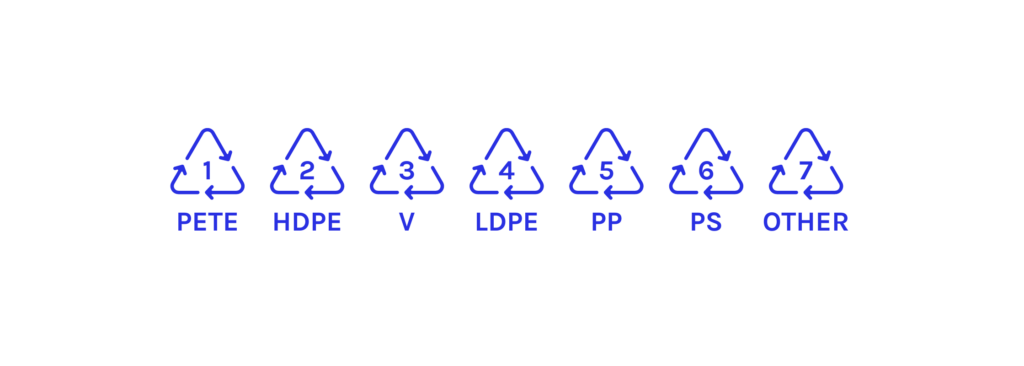

Seven types of plastic are most commonly used for plastic packaging which is the most common application of plastic [2]. The type used is usually indicated on the packaging as a number in a triangle (see below). This is the so-called resin code.

Let’s look at each type in turn:

- PETE: Polyethylene terephthalate. Most plastic bottles and supermarket food trays are made from PETE/PET. Polyester fibres are also made from PETE.

- HDPE: High-density polyethylene. This is the most common rigid plastic, used for things like plastic furniture or toys. It can also be extruded into a foil, though this is less common.

- V or PVC: Polyvinyl chloride. This type is often used for pipes or non-food bottles.

- LDPE: Low-density polyethylene. Almost all basic plastic bags and foils are made of LDPE, but it is also used for containers.

- PP: Polypropylene. Very commonly used for the lid of a plastic bottle, but also most of the plastic parts in a car.

- PS: Polystyrene. Mainly used for lower quality plastic items such as packing cases. However, expanded polystyrene (EPS), known as Styrofoam, is widely used as packaging and insulation material.

- Other: This group comprises all other, less common plastics including compostable plastics.

While these are the most commonly occurring types, there are a lot more types of plastics in use. Even within the most popular categories, similarly labelled plastics may have different chemical compositions. This is the reason why plastic recycling is not as simple as many people think.

The Recycling Process

In general, only one type of plastic can be recycled at a time, meaning an effective plastic recycling process requires a ‘clean stream’ of sorted plastics. Once sorted by type, plastics will have to be sorted a second time by colour if the process is to produce the highest quality of recycled material. Without this, all final plastic materials will be black, brown, or greyish which have significantly less commercial value. Most organisations using recycled plastic want to choose the colour of the products they produce and, for this, the recycled material needs to be transparent or white.

Today, there are three main forms of recycling.

Mechanical Recycling

Mechanical recycling refers to the process of remelting plastic. This requires an exceptionally clean stream of a single plastic type and colour. PET drink bottles are often recycled this way.

Chemical Recycling

Chemical recycling breaks down the molecular structure of plastic, turning it back into base chemicals and chemical feedstocks for reuse. For this process, most plastic types can be mixed. However, this also requires a clean stream of materials, which can be challenging.

Thermal Recycling

Thermal recycling describes the burning of plastic waste to produce energy or steam for municipal heating. This means the material isn’t recycled, instead, it is an end-of-life process.

Challenges In Recycling

As mentioned, different types of plastics cannot simply be recycled together, since they generally have different chemical compositions and/or melting temperatures. However, getting a clean source of a single type of plastic is challenging. Many plastic items are formed from multiple types of plastic, meaning the different parts must be separated or the item fully deconstructed, before recycling is possible. Packaging comprising multiple layers is even harder to recycle as it needs to be delaminated. This is the case with drink cartons. Separation of these materials is costly or even impossible[3].

Of the seven resin-coded plastics, PET and PP are most commonly recycled. Within these plastic types, plastic beverage bottles are recycled in the highest quantities. Most plastic beverage bottles are made only of PET. The beverages that the bottles previously contained generally do not contaminate the plastic with oil or other substances, and the material is transparent. These three factors make PET bottles an appropriate product for recycling.

However, even once recycled, the possible application of recycled plastics is also limited by regulations, hampering plastic reuse.

Post-consumer Plastic Recycling

Regulation controls the type and grade of plastic used for food packaging, to ensure that the packaging will not contaminate the foodstuff. This limits the use of recycled plastic in the EU, as it may contain residue from its previous use. For example, a PET bottle could have been previously used to store a toxic substance [4]. Consequently, almost all food packaging is made from virgin plastic material while post-consumer food packaging can only be used for non-food applications such as household cleaning products and some cosmetics.

However, several companies claim to have developed mechanical recycling processes creating post-consumer plastic which comply with food safety regulations. Of these, the approach with the highest profile is to create a bottle-to-bottle recycling process[5]. Nonetheless, these processes often still require the addition of virgin plastics to guarantee the required quality standard of the material.

The Price of Virgin Plastic

Whether or not plastics are recycled on a large scale depends on the price of virgin plastic and thus the price of oil. A low oil price results in a low price for virgin plastic. The supply of virgin plastic is consistent in both quantity and quality and without the risk of contamination. Recycled plastic struggles to compete as it is often still more expensive because of the complex recycling process and is not perceived to be of the same quality. These challenges result in only 15% of all plastics currently being recycled [6].

Recycling of Riverine Plastics

Recycling of riverine plastic unfortunately is even more challenging. Before addressing the regulatory challenges around post-consumer use, communities need to find an economic solution for collecting, sorting and cleaning the material ready for recycling. Typically, riverine plastic is a lower grade in terms of its chemical and mechanical properties than household plastic waste because of the exposure to UV and mechanical degradation [7].

When riverine plastic is collected, it is often mixed with organic material and the surface of the plastic is subject to biofouling – meaning it is covered with organic matter. Both complicate the sorting effort. Industrial sorting of plastic material uses sensors and lasers which detect the type of plastic based on how it reflects the laser light. If the plastic item is covered with an organic film, the sensor is unable to detect it as plastic. Black plastics face a similar problem, resulting in low recycling rates [8].

Circularity of Plastic Recycling

Cost, regulation and the technical complexities of recycling different types of plastics limit the circular use of plastics. Currently, few recycled plastics are recycled more than once. They need to be consistently returned to the system for reprocessing and reuse.

Even though the challenges above might be discouraging, this does not stop The Great Bubble Barrier from spending time and effort on finding the right recycling partners for the waste our Bubble Barriers capture in rivers. Together with these partners, we are continuously challenging the status quo of plastic recycling.

Author

Philip Ehrhorn

Philip is the co-founder and CTO of The Great Bubble Barrier. He has a background as a Naval Architect and Ocean Engineer and additional education in Aquatic Ecosystem Analysis. He has a strong focus on plastic materials and recycling methods, and he knows how to debunk the many myths surrounding plastic.

References

[1]. Geyer, R., Jambeck, J.R., Law, K.L. (2017). Production, use and fate of all plastics ever made. Science Advances, Volume 3, Issue 7, DOI: 10.1126/sciadv.1700782

[2]. Ibid.

[3]. Ragaert, K., Delva. L., Van Geem, K.M. (2017). Mechanical and chemical recycling of solid plastic waste, Waste Management Volume 69, p. 24-58

[4]. COMMISSION REGULATION (EC) No 282/2008 of 27 March 2008 on recycling of plastic materials articles intended to come into contact with foods and amending Regulation (EC) No 2023/2006

[5]. Welle, F. (2011). Twenty years of PET bottle to bottle recycling—An overview, Resources, Conservation and Recycling Volume 55, Issue 11, September 2011, Pages 865-875

[6]. Wenting Gao, Thomas Hundertmark, Theo Jan Simons, Jeremy Wallach, and Christof Witte (2020). Plastics recycling: Using an economic-feasibility lens to select the next moves

[7]. Andrady, A.L. (2015). Degradation of Plastics in the Environment, Plastics and Environmental Sustainability, p. 145-184

[8]. Robertson, I. (2015). FT-IR and NIR Spectroscopy, Application Note, PerkinElmer